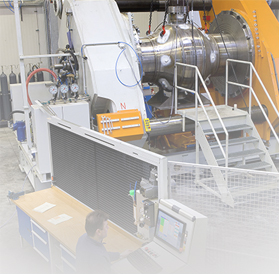

Working principle of American Standard Filter

date:2021-03-20 14:54

When the American standard filter works, the water to be filtered enters from the nozzle, flows through the filter screen, and enters the pipeline required by the user through the outlet for process circulation. The particles and impurities in the water are trapped in the filter screen. With such continuous circulation, more and more particles are intercepted, and the filtering speed is slower and slower. However, the inlet sewage is still flowing in continuously, and the filter hole will be smaller and smaller, resulting in the pressure difference between the inlet and outlet. When the large difference reaches the set value, the differential pressure transmitter transmits the electrical signal to the controller, and the control system starts the drive motor to drive the shaft to rotate through the transmission components At the same time, the drain outlet is opened and discharged from the drain outlet. When the filter screen is cleaned, the differential pressure drops to * small value, and the system returns to the initial filtering state, and the system operates normally. The filter is composed of shell, multi-element filter, backwash mechanism and differential pressure controller.

Working principle of American Standard Filter

The diaphragm in the shell divides the inner cavity into upper and lower cavities. The upper cavity is equipped with multiple filter elements, which makes the filtering space full and significantly reduces the volume of the filter. The lower cavity is equipped with a backwash suction cup. When working, the turbid liquid enters into the lower chamber of the filter through the inlet, and then enters into the inner chamber of the filter element through the diaphragm hole. The impurities larger than the gap of the filter element are intercepted, and the pure liquid passes through the gap and reaches the upper chamber, * and then is sent out from the outlet. The filter adopts high-strength wedge-shaped filter screen, and automatically cleans the filter element through pressure difference control and timing control.

When the impurities in the filter accumulate on the surface of the filter element, causing the pressure difference between the inlet and outlet to increase to the set value, or the timer reaches the preset time, the electric control box will send a signal to drive the backwashing mechanism. When the inlet of the backwashing suction cup is aligned with the inlet of the filter element, the blowdown valve is opened. At this time, the system releases pressure and discharges water. A negative pressure area with relative pressure lower than the water pressure outside the filter element appears on the inner side of the suction cup and the filter element, forcing part of the clean circulating water to flow into the inner side of the filter element from the outer side of the filter element. The impurity particles adsorbed on the inner wall of the filter element flow into the tray with water and discharge from the blowdown valve.

The specially designed filter screen makes the inner part of the filter element produce spraying effect, and any impurities will be washed away from the smooth inner wall. When the pressure difference between the inlet and outlet of the filter returns to normal or the timer set time is over, the material does not stop flow in the whole process, and the backwashing water consumption is small, realizing continuous and automatic production. The filter is widely used in metallurgy, chemical industry, petroleum, papermaking, medicine, food, mining, electric power and urban water supply. Such as industrial wastewater, circulating water filtration, emulsion regeneration, waste oil filtration treatment, continuous casting water system and blast furnace water system in metallurgical industry, high pressure water descaling system for hot rolling. It is an advanced and easy to operate automatic filtering device.